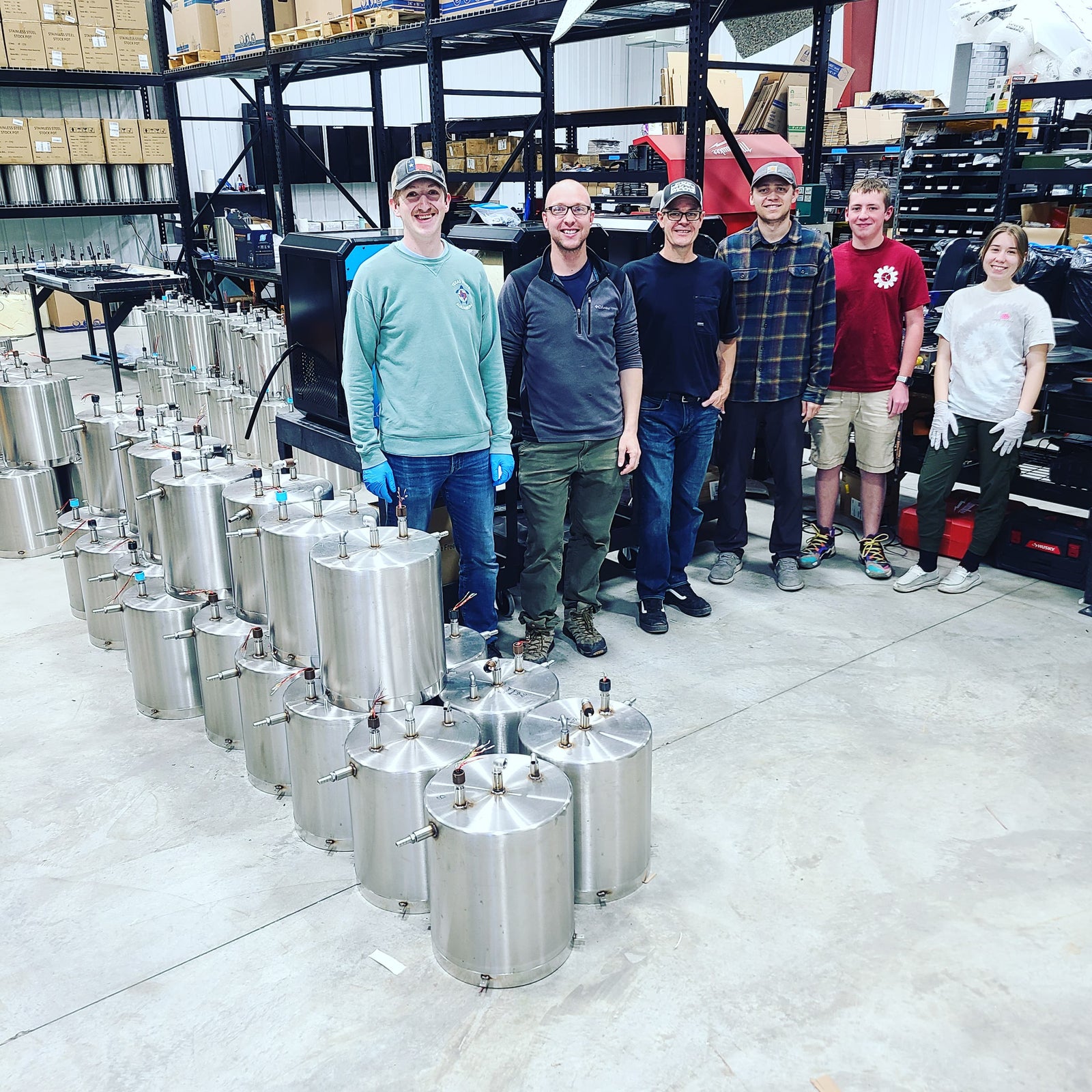

Who We Are

We are a proud team located in Saint Anthony, Idaho. Founded by three brothers, we value community through all facets of our business. As we continue to grow and add to our team, we look to bring on the best of our local talent to give you a home grown product that you can count on.

Here at Blue Alpine, we are serious about three things: freeze dryers, quality, and customer service. We have spent the last five years researching, engineering, and testing our freeze dryers to make them the highest quality possible.

A lot of small improvements add up to a huge difference in quality to make our freeze dryer a superior machine. Below are some of the highlights of that stand out: